TACTEL® is a branded nylon fibre known for its lightweight construction, softness, durability, and fast-drying performance. It is widely used in motorcycle clothing and performance apparel where comfort, breathability, and long-term wear resistance are important.

History and development

TACTEL was developed as a next-generation nylon fibre designed to improve upon traditional polyamide textiles. The aim was to create a material that retained the strength and durability of nylon while offering improved softness, reduced weight, and faster moisture evaporation. Over time, TACTEL has been adopted across performance clothing sectors, including motorcycle apparel, where lightweight comfort and moisture management are critical.

Composition and technology

TACTEL is produced using high-performance nylon microfibres that are engineered to be finer and lighter than conventional nylon yarns. This microfibre construction allows fabrics made with TACTEL to deliver a softer hand feel while maintaining strength and durability.

The fibre structure also increases surface area within the yarn, improving moisture transport and evaporation. This contributes to the fabric’s fast-drying properties and breathable performance, particularly in warm riding conditions.

Key material characteristics

- Softness - engineered to be significantly softer than standard nylon textiles.

- Lightweight construction - approximately 20 percent lighter than many traditional fibres.

- Fast drying - dries considerably faster than cotton-based fabrics.

- Strength - produces fabrics up to three times stronger than comparable natural fibre textiles.

- Moisture management - helps move sweat away from the skin for improved comfort.

Protective and performance role in motorcycle clothing

Unlike heavy-duty reinforcement fabrics such as CORDURA or SuperFabric, TACTEL is primarily used as a comfort and performance textile rather than a primary abrasion barrier. In motorcycle clothing, it is commonly selected for areas where airflow, flexibility, and reduced weight are priorities.

Applications in motorcycle clothing

TACTEL is frequently used in ventilated jackets, summer riding trousers, base layers, inner linings, and mesh panels. Its lightweight structure and moisture-wicking behaviour make it well suited for warm-weather riding gear and long-distance comfort.

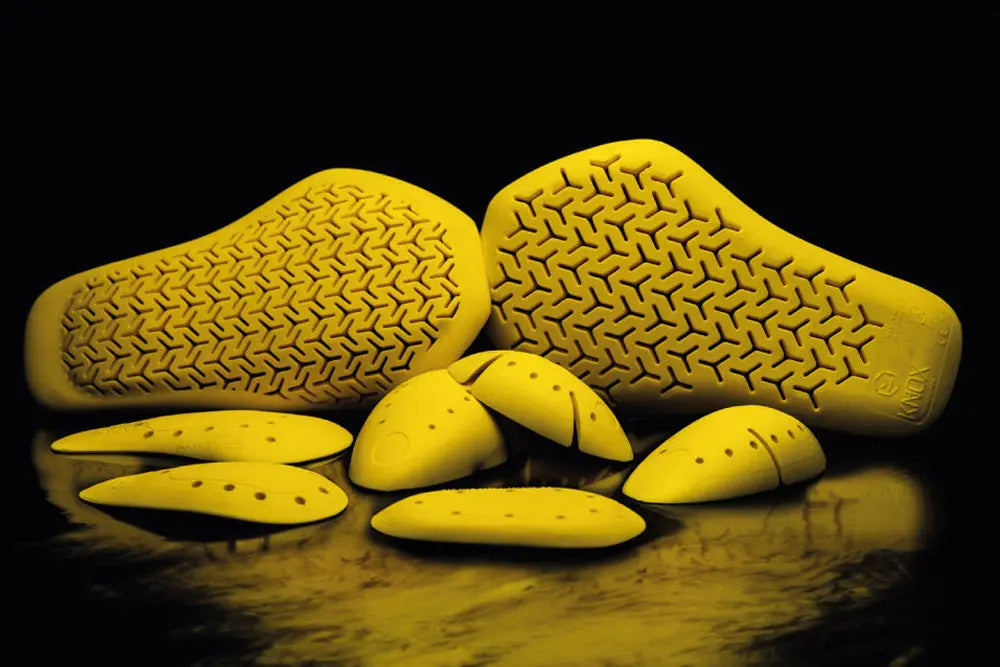

Manufacturers often combine TACTEL with impact protectors, abrasion-resistant outer shells, and weather membranes to create balanced garments that offer both protection and rider comfort.

Motorcycle brands known to use TACTEL®

- Rebelhorn - incorporates TACTEL into selected jackets and trousers to improve breathability and lightweight comfort.

- Dainese - has used TACTEL fabrics in ventilation panels and performance textile apparel.

- Rev’it - integrates lightweight nylon blends, including TACTEL-based fabrics, in summer riding gear.

- Held - uses TACTEL materials in comfort-focused liners and airflow-oriented garments.

Comparison with other motorcycle textiles

TACTEL is often compared with standard nylon and polyester fabrics used in motorcycle clothing. While conventional nylons offer durability, TACTEL provides improved softness, reduced weight, and enhanced moisture management. Compared with heavy-duty abrasion-resistant textiles such as CORDURA or aramid reinforcements, TACTEL serves a complementary role by improving comfort and rider mobility rather than replacing protective outer shells.

Variants and fabric blends

TACTEL fibres are available in multiple yarn constructions and are commonly blended with elastane or combined with mesh structures to increase stretch and airflow. These variations allow manufacturers to tailor garments for specific climates, riding styles, and comfort requirements.

Care and maintenance

TACTEL garments should be washed according to manufacturer guidelines to preserve moisture-wicking performance and fabric structure. Avoiding excessive heat during washing and drying helps maintain fibre integrity and long-term comfort characteristics.